Trampoline testing standards verify frame strength, bounce durability, and material quality. Without them, products may corrode, sag, or fail prematurely. Certified models like Akrobat meet ASTM, EN, TÜV, and REACH standards for long-term, consistent performance.

If you’re thinking about buying a trampoline, there’s something more important than size, shape, or price: how it’s tested.

Most trampolines sold today are never put through third-party testing. Some brands boast high weight limits or flashy features, but skip the certifications that actually verify structural integrity, bounce consistency, and long-term durability.

That’s why at AkrobatUSA, we don’t cut corners. Every trampoline we distribute is manufactured by Akrobat in Europe and certified to meet or exceed the strictest standards in the industry: ASTM, EN 71-14, EN 13219, TÜV, and REACH.

From hot-dip galvanized frames to tear-resistant mats tested for over 2.5 million jumps, Akrobat trampolines are proven. Whether you’re buying for backyard fun or sports training, you’ll know your investment was made with transparency and quality.

If you want to dig deeper, learn exactly what those standards mean, why they matter, and how to spot the red flags other brands hope you miss, keep reading.

What Are Trampoline Testing Standards?

Featured Product: XCITYX 17ft x 12ft Akrobat Above Ground Trampoline – Printed Blue Pad and Blue Jump Mat

Trampoline testing standards are guidelines developed by international regulatory bodies to evaluate trampolines. While these standards are not legally required in the United States, they exist to ensure the product has been rigorously tested for real-world use.

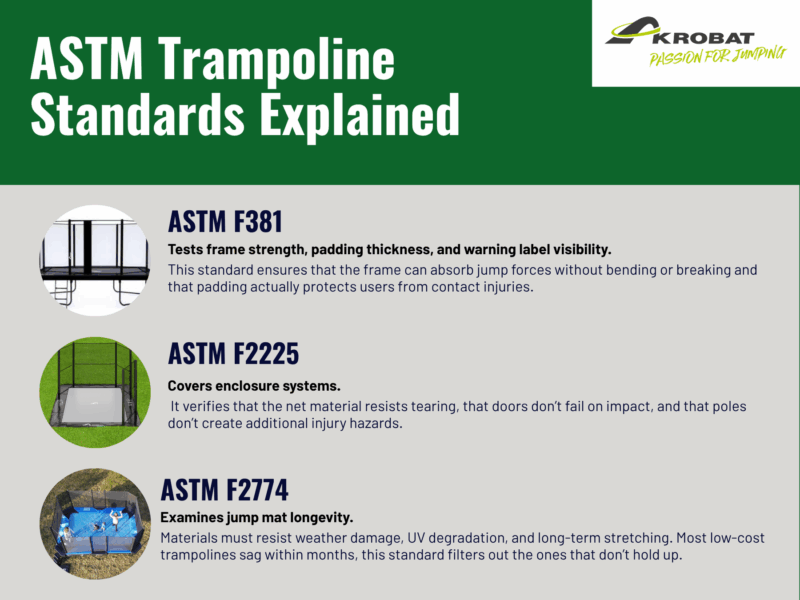

The most relevant certifications include:

- ASTM F381 (U.S.): Standard Safety Specification for Components, Assembly, Use, and Labeling of Consumer Trampolines (currently F381-24) Defines safety requirements covering key components (frame, bed, suspension, padding), assembly procedures, labeling, shock‑attenuation, drop testing, padding retention, UV resistance, static load testing, and information/instructions for use.

- ASTM F2225 — Standard Safety Specification for Consumer Trampoline Enclosures (currently F2225-24) Scope: Covers safety and performance criteria for trampoline enclosures (nets and supporting structures), including tests for net material durability, minimum heights, secure bottom attachments to prevent sliding underneath, impact resistance, proper labeling, and component packaging

- ASTM F2774 — Standard Practice for Manufacturing Quality Control of Consumer Trampoline Bed Material (currently F2774-24) Scope: Focuses on manufacturing quality control for trampoline beds, providing guidelines for sampling methods, testing frequencies, and QC test types—ensuring that trampoline mats meet consistent, statistically valid quality standards during production

- EN 71-14 (EU): Evaluates materials for UV resistance and weather durability, particularly relevant for backyard trampolines.

- EN 13219 and EN 913: These cover requirements for gymnastic-level trampolines and ensure that equipment can handle higher, more technical bounce usage.

Unfortunately, most trampolines on the market skip these entirely.

That’s a problem, especially when parents assume every product goes through the same process. Without certification, there’s no way to know how it will perform, or how long it will last.

Why Material Quality and Durability Matter for Families

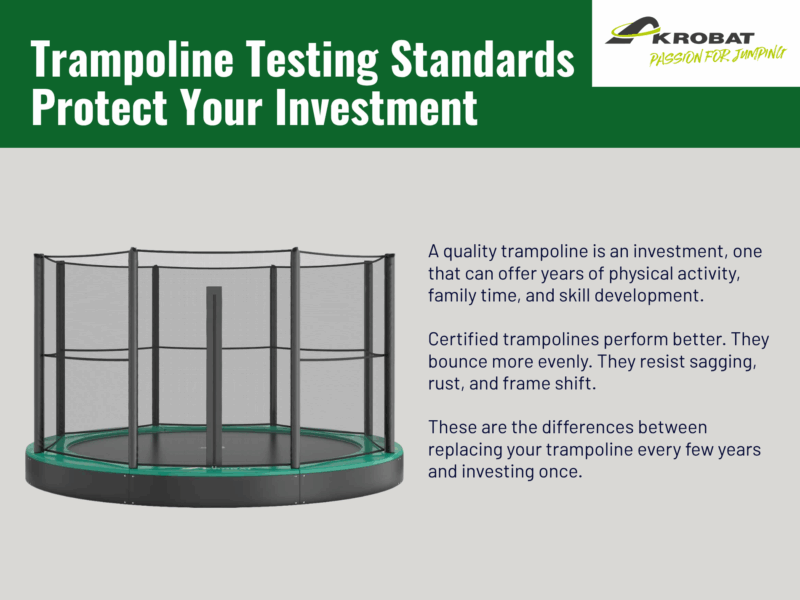

For families investing in a trampoline, long-term performance and material resilience should be non-negotiable. Unfortunately, many brands skip rigorous material testing in favor of lower costs.

That trade-off shows up fast:

- Low-grade steel frames often use light, powder-coated tubing prone to internal rusting. Without hot-dip galvanization, corrosion can begin from the inside, even in dry climates.

- Padding and netting materials wear out quickly when exposed to sun and moisture. Within months, they may lose compression, fade, or crack, especially if they haven’t passed UV resistance testing.

- Bounce mats made from generic polyester blends often lose elasticity after repeated use. This results in uneven bounce and surface sagging that disrupts consistency.

Akrobat trampolines are built to avoid all of that. Every unit is engineered in Europe using premium, tested materials, that hold their structure through years of use.

Answering Key Questions About Trampoline Testing

When people research trampolines, the same core questions tend to surface. Let’s break them down with no fluff, just the facts.

- What is the ASTM standard for trampolines? The ASTM standards, especially F381, F2225, and F2774, cover frame design, enclosure safety, padding quality, and mat durability.

- Why do you need 6’ around a trampoline? Because the most dangerous accidents don’t happen mid-air, they happen when someone falls off into an object. That 6’ space acts as a buffer to prevent collisions with fences, trees, or hard surfaces.

- Are European trampoline standards stricter than American ones? Yes. European certifications like EN 71-14, EN 1176, and TÜV include testing for UV resistance, extreme weather, and chemical safety. These go beyond what ASTM requires in the U.S., particularly around environmental durability and material toxicity.

What Trampolines Often Miss (and Why It’s a Problem)

Most trampolines sold in big-box stores or online marketplaces skip third-party testing altogether. The result? Products that seem solid at first but fail under real-world use.

- CE certified ≠ tested: The CE mark is self-declared. Any manufacturer can apply it without external verification. It creates a false sense of assurance for families who assume it equates to tested safety.

- Misleading weight ratings: Structural capacity, how much a trampoline can support when no one’s moving, isn’t useful without dynamic weight testing. A trampoline that “holds 1,200 lbs” may fail under a 200 lb jumper if it wasn’t tested dynamically.

- Unreliable nets and compressed padding: UV exposure degrades cheap enclosure nets in months. Padding flattens out and fails to protect against frame contact. Many brands don’t list specs because they don’t meet durability benchmarks.

- Material safety risks: Without REACH or TÜV certification, there’s no guarantee that foam, coatings, or fabrics are free from toxins. Families often assume these products are regulated, when they’re not.

- Frames that corrode without warning: Trampolines built with thin, powder-coated steel (instead of hot-dip galvanized steel) begin rusting internally, often invisible until the frame fails under load. These failures usually show up after the warranty runs out.

How Akrobat Trampolines Go Beyond the Standard

Featured Product: 14ft x 10ft Akrobat Primus Flat Special Edition Black on Black In-ground Trampoline

Akrobat trampolines are engineered for longevity, performance, and trust. Every unit is built in Europe, tested independently, and distributed by AkrobatUSA with full transparency. Here’s what sets them apart:

- Third-party tested to ASTM, EN, TÜV, and REACH standards

- Frames rated for 2.5 million jumps, a true endurance benchmark

- Hot-dip galvanized steel for maximum corrosion resistance

- AkroSPRING® springs made from 3.2mm galvanized wire for extended lifespan

- AkroVENT® mat allows 62.7% airflow for softer landings and reduced joint stress

- AkroCLICK® assembly eliminates screws and misalignments that cause frame weakness

- UV-tested safety pads and tear-resistant nets built for multi-season durability

Final Checklist Before You Buy

Before you commit to any trampoline purchase, walk through this quick checklist. If the answer to any of these questions is “no,” it’s worth looking again.

- ✅ Does it have ASTM or EN certifications?

- ✅ Is the frame made of hot-dip galvanized steel?

- ✅ Are springs and mats tested for millions of jumps?

- ✅ Is the bounce surface UV- and weather-resistant?

- ✅ Is there a clear difference between static and dynamic weight ratings?

- ✅ Does the enclosure use UV-treated, tear-resistant netting?

- ✅ Are the assembly points engineered to reduce long-term wear?

With Akrobat trampolines, every one of these boxes is checked.

Ready for Better? Choose a Trampoline That’s Actually Tested

Akrobat delivers engineered proof that your trampoline will keep performing long after others have failed.

At AkrobatUSA, that’s exactly what we offer:

- Akrobat trampolines are third-party certified (ASTM, EN, TÜV, REACH) and built in Europe with full testing transparency.

- Akrobat’s hot-dip galvanized frames are several hundred pounds heavier than typical models, with tool-free AkroCLICK® assembly that eliminates weak points.

- AkroVENT® jump mats and AkroSPRING® systems maintain bounce quality over 2.5 million jumps, quiet, smooth, and controlled.

You’re not just buying a product. You’re investing in peace of mind, for every jump, flip, and landing to come.

TÜV (pronounced “toof”) is short for Technischer Überwachungsverein, which translates from German as Technical Inspection Association.

Here’s what that means in practice:

Overview

- TÜV is not a single company—it’s a group of independent German organizations (like TÜV SÜD, TÜV Rheinland, TÜV NORD) that test, inspect, and certify products, systems, and processes for safety, quality, and compliance.

- Originally founded in the late 1800s to inspect steam boilers, TÜV groups now work globally in industries ranging from consumer goods to automotive, medical devices, manufacturing, and energy systems.

Role in Trampolines

For trampolines and other recreational products, TÜV:

- Tests products to recognized safety standards (such as ASTM, EN, ISO, or its own TÜV/GS standards).

- Provides the TÜV mark or GS (“Geprüfte Sicherheit”) mark if a product meets the relevant safety and quality requirements.

- In many European markets, TÜV or GS certification is a strong selling point because it shows independent third-party safety verification.